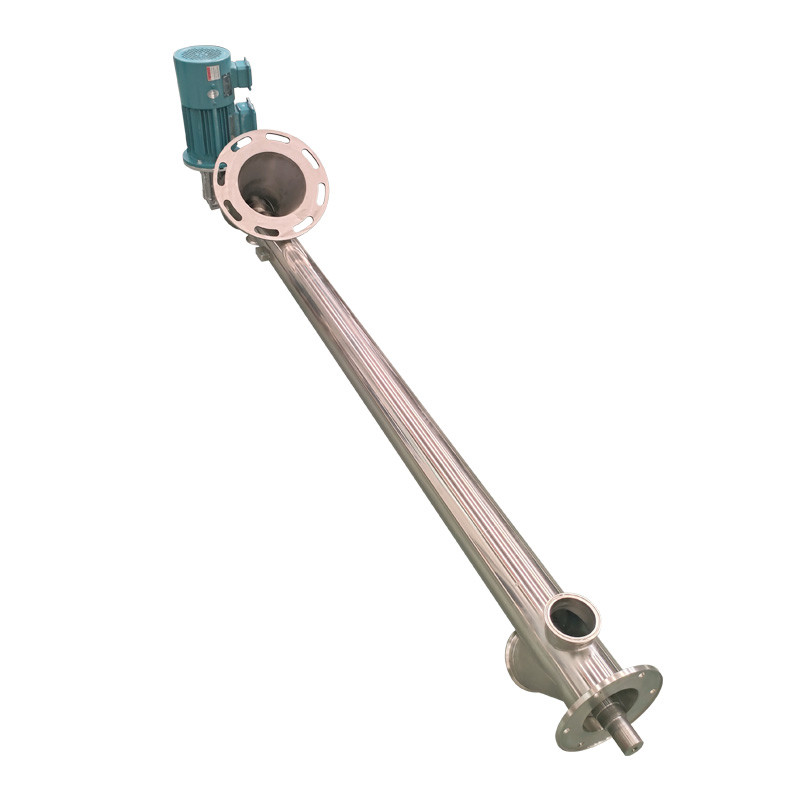

স্ক্রু পরিবাহক

পণ্যের বর্ণনা

স্ক্রু পরিবাহকগুলি শিল্প উৎপাদনে সাধারণত ব্যবহৃত উপাদান পরিবহন সরঞ্জাম। এগুলি স্ক্রু ব্লেডের ঘূর্ণনের মাধ্যমে একটি বন্ধ চ্যানেলের মধ্যে উপাদানগুলিকে ঠেলে। এই মেশিনের গঠন জটিল নয়। মূল অংশটি হল ব্লেডযুক্ত একটি ঘূর্ণায়মান শ্যাফ্ট, ইউ-আকৃতির বা নলাকার উপাদান খাঁজ, এবং ড্রাইভ মোটরগুলির মতো উপাদান দিয়ে সজ্জিত। এটির অনেক সুবিধা রয়েছে, যেমন অল্প স্থান নেয়, অনুভূমিক বা তির্যক দিকে উপাদান সরবরাহ করতে পারে এবং উপাদান লিক বা ধুলো দূষণ রোধ করার জন্য ভালভাবে সিল করা থাকে। রাসায়নিক কারখানায় সার এবং রঙ্গক সরবরাহ করা থেকে শুরু করে শস্য মিলে গম এবং ময়দা পরিবহন করা এবং তারপরে বিল্ডিং ম্যাটেরিয়াল কারখানায় সিমেন্ট এবং বালি সরবরাহ করা পর্যন্ত, এটি পাউডার এবং কণাগুলির মতো উপকরণগুলি ক্রমাগত পরিবহনের জন্য অনেক জায়গায় ব্যবহার করা যেতে পারে। এটি ব্যবহার করা নমনীয় এবং সুবিধাজনক।

কাজের নীতি

একটি স্ক্রু পরিবাহকের কার্যকারী নীতি যান্ত্রিক ট্রান্সমিশনের উপর কেন্দ্রীভূত: যখন ড্রাইভ ডিভাইস স্ক্রু শ্যাফ্ট ঘোরায়, তখন স্ক্রু ব্লেডগুলি সেই অনুযায়ী ঘোরে এবং উপাদানের উপর একটি অক্ষীয় ধাক্কা প্রয়োগ করে। উপাদানের সাথে খাঁজের ভিতরের দেয়ালের ঘর্ষণ বলের কারণে এবং উপাদানের উপর মাধ্যাকর্ষণ শক্তির প্রভাবের কারণে, এটি ব্লেডের সাথে ঘুরতে পারে না। পরিবর্তে, ধাক্কার অধীনে, এটি খাওয়ানো পোর্ট থেকে স্রাব পোর্টের দিকে খাঁজের অক্ষীয় দিক বরাবর চলে, যার ফলে অবিচ্ছিন্ন উপাদান পরিবহন সম্পন্ন হয়। হেলিকাল ব্লেডের ঘূর্ণন দিক সামঞ্জস্য করে পরিবহনের দিকটি নমনীয়ভাবে পরিবর্তন করা যেতে পারে। এই প্রক্রিয়াটি যা হেলিকাল কাঠামোর মাধ্যমে ঘূর্ণন শক্তিকে অক্ষীয় ধাক্কায় রূপান্তরিত করে, সরঞ্জামটিকে পাউডার, কণা এবং ছোট ব্লক উপকরণগুলির পরিবহনের প্রয়োজনীয়তা দক্ষতার সাথে পরিচালনা করতে সক্ষম করে।

পণ্যের বৈশিষ্ট্য

1. কমপ্যাক্ট এবং নমনীয় কাঠামো: সরঞ্জামটি সুন্দরভাবে স্থাপন করা হয়েছে, একটি ছোট এলাকা দখল করে এবং অনুভূমিক, তির্যক বা এমনকি উল্লম্ব ইনস্টলেশন পরিবেশের সাথে মানিয়ে নিতে পারে, যা এটিকে উত্পাদন লাইনের বিভিন্ন লিঙ্কে একত্রিত করা সহজ করে তোলে।

2. স্থিতিশীল পরিবহন দক্ষতা: সর্পিল ব্লেডগুলি ক্রমাগত উপাদানগুলিকে ঠেলে, অভিন্ন এবং অবিচ্ছিন্ন পরিবহন অর্জন করে, বিশেষ করে পাউডার, কণা এবং ছোট ব্লক উপকরণগুলির জন্য উপযুক্ত।

3. চমৎকার সিলিং কর্মক্ষমতা: বন্ধ উপাদান খাঁজ ডিজাইন কার্যকরভাবে ধুলো বাইরে ছিটানো এবং উপকরণ আর্দ্র হওয়া থেকে আটকাতে পারে, পরিবেশ দূষণ হ্রাস করে এবং একই সাথে উপাদানের বিশুদ্ধতা নিশ্চিত করে, খাদ্য, রাসায়নিক এবং অন্যান্য শিল্পের পরিষ্কার দৃশ্যের প্রয়োজনীয়তা পূরণ করে।

4. সুবিধাজনক দিক সমন্বয়: সর্পিল ব্লেডের ঘূর্ণন দিক পরিবর্তন করে, বিভিন্ন প্রক্রিয়ার উপাদান স্থানান্তর প্রয়োজনীয়তা মেটাতে উপাদানের পরিবহন পথ সহজেই পরিবর্তন করা যেতে পারে।

5. কম রক্ষণাবেক্ষণ খরচ: মূল উপাদানগুলির একটি সাধারণ গঠন রয়েছে এবং দুর্বল অংশগুলির প্রতিস্থাপন সুবিধাজনক। প্রতিদিন শুধুমাত্র নিয়মিত পরিদর্শন এবং লুব্রিকেশন প্রয়োজন, যা শাটডাউন রক্ষণাবেক্ষণের খরচ কমিয়ে দেয়।

অ্যাপ্লিকেশন শিল্প

রাসায়নিক শিল্প: এটি সোডা অ্যাশ, সার এবং রঙ্গকগুলির মতো পাউডার বা দানাদার রাসায়নিক কাঁচামাল পরিবহনের জন্য ব্যবহৃত হয় এবং উপকরণগুলির ব্যাচিং, মিশ্রণ এবং প্যাকেজিংয়ে একটি ভূমিকা পালন করে।

শস্য এবং খাদ্য প্রক্রিয়াকরণ: এটি গম, ভুট্টা, ময়দা এবং পাউডার চিনির মতো উপকরণ পরিবহনের জন্য উপযুক্ত এবং সাধারণত শস্য সংরক্ষণ, ফিড প্রক্রিয়াকরণ এবং খাদ্য উত্পাদন লাইনে পাওয়া যায়।

বিল্ডিং ম্যাটেরিয়ালের ক্ষেত্রে: এটি সিমেন্ট, কয়লা পাউডার এবং বালির কণাগুলির মতো বিল্ডিং ম্যাটেরিয়াল সরবরাহ করতে পারে এবং কংক্রিট মিশ্রণ প্ল্যান্ট, বিল্ডিং ম্যাটেরিয়াল স্টোরেজ এবং পরিবহন সিস্টেমে ব্যাপকভাবে ব্যবহৃত হয়।

ধাতুবিদ্যা এবং খনির শিল্প: এটি আকরিক পাউডার, কয়লা পাউডার এবং কোকের মতো উপকরণ পরিবহনের জন্য ব্যবহৃত হয় এবং আকরিক স্ক্রিনিং এবং গন্ধকরণের প্রিট্রিটমেন্টের মতো প্রক্রিয়াগুলিতে উপাদান স্থানান্তর উপলব্ধি করে।

পরিবেশ সুরক্ষা এবং কৃষি: এটি কাদা এবং খড়ের পেলিটের মতো পরিবেশ বান্ধব উপকরণগুলি পরিচালনা করতে পারে বা কৃষিতে বীজ, ফিড ইত্যাদি পরিবহন করতে পারে, বিভিন্ন দৃশ্যের উপাদান পরিবহনের চাহিদা পূরণ করে।

পণ্যের প্যারামিটার

| মডেল |

পরিবহন টিউব ব্যাস |

পাওয়ার |

হপার ভলিউম |

কোণ(ডিগ্রী) |

| ESC-133 |

133 মিমি |

0.75-4KW |

200L বা কাস্টমাইজড |

30-60 |

| ESC-159 |

159 মিমি |

0.75-4KW |

| ESC-219 |

219 মিমি |

1.5-4KW |

| ESC-273 |

273 মিমি |

2.2-4KW |

| আরও মডেলের জন্য আমাদের সাথে পরামর্শ করুন |

|

পণ্য প্রদর্শন

পণ্যের বিবরণ

পণ্য অ্যাপ্লিকেশন

প্যাকেজিং ও শিপিং

কেন আমাদের নির্বাচন করবেন

আমাদের সম্পর্কে

আমরা 13 বছর ধরে স্ক্রিনিং এবং পরিবাহক সরঞ্জাম উৎপাদনে বিশেষজ্ঞতা অর্জন করেছি। চীনের ভাইব্রেটিং স্ক্রিন শিল্পের শীর্ষ তিনটি। এবং আমরা অনেক বড় কোম্পানির জন্য ম্যাচিং এবং OEM করেছি। বিশ্বের শীর্ষ ভাইব্রেটিং স্ক্রিন প্রস্তুতকারক, Sweco, USA সহ, আমরা তার চীন অঞ্চলের জন্য OEM করেছি। এবং আমাদের পণ্যগুলি প্রায়শই অস্ট্রেলিয়া, থাইল্যান্ড, ইন্দোনেশিয়া, নিউজিল্যান্ড এবং অন্যান্য দেশে রপ্তানি করা হয়।আমরা গ্রাহক বা ডিলারদের আমাদের কারখানা পরিদর্শনের জন্য স্বাগত জানাই এবং আপনার জন্য সবকিছু ব্যবস্থা করব। আমাদের কারখানার ঠিকানা: দা ঝাওয়িং টাউনের শিল্প ও বাণিজ্যিক অফিসের পশ্চিমে, জিনজিয়াং সিটি, হেনান প্রদেশ।

আপনার বার্তাটি 20-3,000 টির মধ্যে হতে হবে!

আপনার বার্তাটি 20-3,000 টির মধ্যে হতে হবে! অনুগ্রহপূর্বক আপনার ইমেইল চেক করুন!

অনুগ্রহপূর্বক আপনার ইমেইল চেক করুন!  আপনার বার্তাটি 20-3,000 টির মধ্যে হতে হবে!

আপনার বার্তাটি 20-3,000 টির মধ্যে হতে হবে! অনুগ্রহপূর্বক আপনার ইমেইল চেক করুন!

অনুগ্রহপূর্বক আপনার ইমেইল চেক করুন!